Our newly developed atomizer quick change system with automatic lock for more efficient atomizer change is ready and available for you!

Problem definition during atomizer change

The current high rotation atomizers are heavy, often angled 60° and therefore quite bulky and unwieldy. Unscrewing the 3 thumbscrews on the previous laboratory units and holding the atomizer at the same time requires some practice and strength.

Once all 3 screws have been completely unscrewed from the thread, the exchange plate with the atomizer can be removed from the master plate.

can be removed. Care must be taken that the atomizer does not slip off beforehand.

Placing the exchangeable plate, with the atomizer attached to it, on the master plate also requires some practice, as the sealing pins in the master plate must exactly match the holes in the exchangeable plate. Only when the exchangeable plate is completely seated on the master plate, do you hold the atomizer on the master plate with one hand and tighten the knurled screws with the other hand.

Especially when placing the atomizer, it can happen that the coupling for the bearing air breaks off or O-rings are damaged. This leads to malfunctions in the system and thus to downtime and possible repair costs.

Due to the working position, this activity is particularly stressful for small employees.

In order to avoid the above-mentioned problems, we have often been approached by our customers to shorten and simplify this changing process.

Our Solution

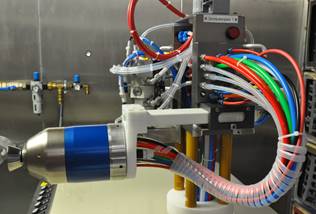

The removable plate is locked on the master plate using a tested robot tool changing system that has been adapted to the requirements of laboratory systems:

- The tool changer is unlocked and locked pneumatically at the push of a button.

- In the event of a compressed air failure, the atomizer remains self-retaining on the master plate.

- The controller recognizes whether an atomizer has been adapted.

- As an option, we offer automatic atomizer detection.

- A handle on the removable plate simplifies the handling of the atomizer significantly. Keep both hands on the atomizer when locking and unlocking.

- All sealing systems have been optimized for low wear.

- By changing the atomizer, no seals can be destroyed.

- There is no self-closing air coupling for the bearing clearance that could break off.

- The centering of the atomizer removable plate on the master plate is very easy using a centering bar and centering bolt.

- To reduce the risk of injury, the atomizer can only be changed if all paint and solvent hoses have been rinsed and dried beforehand.

- The atomizer change takes just 18 seconds (see video).

Conclusion

The new changing system significantly reduces operating costs by

- higher system availability

- lower maintenance costs

- shorter atomizer change times

- The atomizer can be changed during the exhaust air time between two spray coats

- reduced workload of employees when changing atomizers